Efficient Liquid Level Control in Industrial Storage Tanks

Efficient Liquid Level Control in Industrial Storage Tanks

1. Introduction

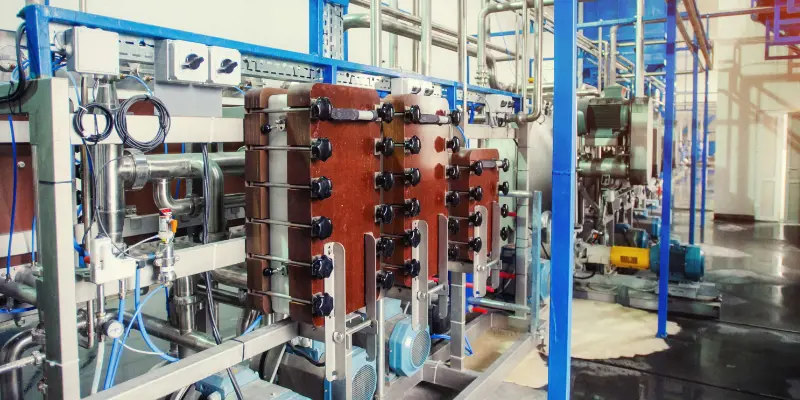

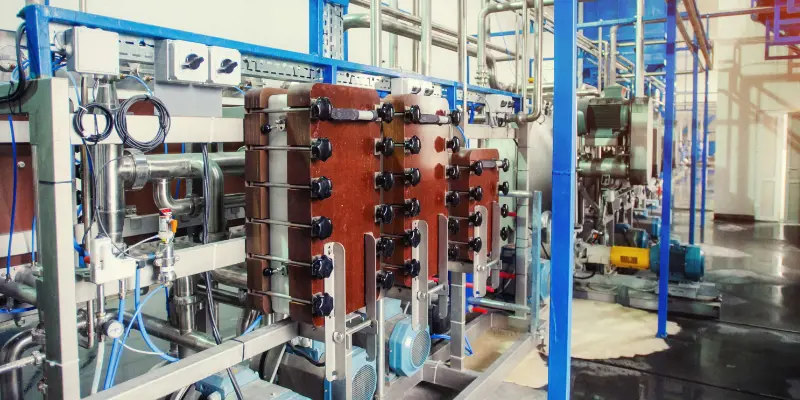

In industrial facilities, accurate liquid level control is essential for operational efficiency, safety, and regulatory compliance. Storage tanks used in chemical processing, food and beverage production, and manufacturing require precise monitoring to prevent overflows, ensure consistent supply, and optimize inventory management. Traditional level sensors often struggle with reliability in harsh industrial environments, making radar level sensors the preferred choice. In industrial facilities, accurate liquid level control is essential for operational efficiency, safety, and regulatory compliance. Storage tanks used in chemical processing, food and beverage production, and manufacturing require precise monitoring to prevent overflows, ensure consistent supply, and optimize inventory management. Traditional level sensors often struggle with reliability in harsh industrial environments, making radar level sensors the preferred choice.

2. Challenges in Industrial Liquid Level Monitoring

Industrial storage tanks present several challenges:

- Varying Liquid Properties : Some liquids produce foam, steam, or vapor that can interfere with traditional sensors.

- Extreme Conditions : High temperatures, pressure fluctuations, and aggressive chemicals affect sensor durability.

- Difficult Sensor Accessibility : Storage tanks are often located in restricted or hazardous areas.

3. Advantages of a Radar Level Sensor

Our radar level sensor provides an advanced solution with:

- Non-Contact, High-Accuracy Measurement : Ensures reliable readings without being affected by vapor, foam, or surface turbulence.

- 10-Meter Measurement Range : Suitable for various industrial tank sizes.

- ±2mm Accuracy : Delivers precise level monitoring, reducing material waste and improving efficiency.

- Bluetooth Configuration : Enables remote sensor adjustments via a mobile app (iOS & Android), eliminating the need for physical access.

- IP68 Protection & Durable Construction : Designed for harsh industrial environments, resistant to chemicals and extreme temperatures.

4. Applications in Industrial Storage Tanks

- Chemical Storage Tanks : Prevents hazardous overflows and maintains proper chemical levels.

- Food & Beverage Processing Tanks : Ensures precise ingredient storage and reduces contamination risks.

- Manufacturing & Process Liquids : Optimizes raw material usage and inventory control.

5. Conclusion

Implementing a radar level sensor for industrial storage tanks enhances process reliability, reduces maintenance costs, and improves overall efficiency. With non-contact technology, Bluetooth adjustability, and high precision, this sensor is an essential tool for modern industrial liquid-level management.

Need a better solution for your industrial tank level monitoring? Contact us today to explore how our radar level sensors can optimize your operations!

Related Posts

Chemical Dosing in Water Treatment Systems

In modern water treatment systems, accurate chemical dosing is essential to ensure proper purification, prevent scaling, and maintain optimal pH levels. Traditional dosing methods using mechanical flow meters often lack the precision and reliability needed for consistent performance. This is where an electromagnetic flow meter designed for small-diameter pipelines becomes an ideal solution.

Precise pH and Conductivity Monitoring in Water Treatment Plants

In modern water treatment plants, maintaining the correct pH and conductivity levels is essential to ensure water quality, regulatory compliance, and efficient chemical dosing. Without precise monitoring, facilities may experience inefficient treatment, excessive chemical usage, and potential environmental violations. Traditional monitoring methods often lack the necessary accuracy and automation features required for modern industrial water treatment.

Optimizing Drying Processes in the Food Industry

In food production, precise humidity control plays a critical role in ensuring product quality, shelf life, and energy efficiency. Whether drying nuts, fruits, or baked goods, achieving the correct moisture level is essential for maintaining texture and flavor while preventing spoilage. Traditional humidity sensors often fail in high-temperature drying environments, making an industrial high-temperature humidity sensor a necessary solution.

pH and Conductivity Control in Industrial Cooling Towers

Cooling tower systems are essential for temperature regulation in industrial facilities, power plants, and HVAC systems. However, maintaining proper pH and conductivity levels is crucial to prevent scaling, corrosion, and microbiological growth. Inadequate monitoring can lead to equipment failures, excessive chemical use, and increased operational costs.

Chemical Dosing in Water Treatment Systems

In modern water treatment systems, accurate chemical dosing is essential to ensure proper purification, prevent scaling, and maintain optimal pH levels. Traditional dosing methods using mechanical flow meters often lack the precision and reliability needed for consistent performance. This is where an electromagnetic flow meter designed for small-diameter pipelines becomes an ideal solution.

Precise pH and Conductivity Monitoring in Water Treatment Plants

In modern water treatment plants, maintaining the correct pH and conductivity levels is essential to ensure water quality, regulatory compliance, and efficient chemical dosing. Without precise monitoring, facilities may experience inefficient treatment, excessive chemical usage, and potential environmental violations. Traditional monitoring methods often lack the necessary accuracy and automation features required for modern industrial water treatment.

Optimizing Drying Processes in the Food Industry

In food production, precise humidity control plays a critical role in ensuring product quality, shelf life, and energy efficiency. Whether drying nuts, fruits, or baked goods, achieving the correct moisture level is essential for maintaining texture and flavor while preventing spoilage. Traditional humidity sensors often fail in high-temperature drying environments, making an industrial high-temperature humidity sensor a necessary solution.

pH and Conductivity Control in Industrial Cooling Towers

Cooling tower systems are essential for temperature regulation in industrial facilities, power plants, and HVAC systems. However, maintaining proper pH and conductivity levels is crucial to prevent scaling, corrosion, and microbiological growth. Inadequate monitoring can lead to equipment failures, excessive chemical use, and increased operational costs.